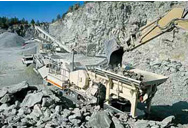

convoyeur a courroie de caoutchouc en venezuela POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- cement vertical mill reducer

- convoyeur en pvc amérique du sud

- fabricant de moules de ciment

- materiel de carriere en granite doccasion en californie

- densidad del triturado de concreto

- sable utilise faisant la machine

- marché des Minerai de fer equipements de granulats en inde

- Probleme De Beton Avec Sable De Concassage

- usine de traitement de sable architectural

- gold mine profits

- mines de charbon adaro

- concasseurs à gravier en circuit fermé occasion

- les collèges qui offrent des magasins à eldoret

- machines utilisées pour le broyage de grammes rouges

- broyeur de pierre diamant

de l usine de ciment en jordanie types

Fraisage au diamant 101 - Processus d'usinage, outils, types de ...

2023.9.19 Alors que les industries recherchent sans relâche l’efficacité et la précision, l’incorporation de broyeurs diamantés a modifié les processus de fabrication et d’usinage. Cet article illustre le fraisage au diamant, ses outils, ses applications et l'avantage qu'il apporte à l'ingénierie moderne.

Read More

Broyeur De Pierre À Diamant Hydraulique,Vente En Gros

Broyeur De Pierre À Diamant Hydraulique,Vente En Gros,Fabricant En Chine,De Cône Hydraulique,Série Hp Avec Une Grande Capacité , Find Complete Details about Broyeur De Pierre À Diamant Hydraulique,Vente En Gros,Fabricant En Chine,De Cône Hydraulique,Série Hp Avec Une Grande Capacité,Hydraulique Concasseur À Cône Prix

Read More

Le petit outillage du diamantaire - Valuae

Sommaire du chapitre : Le petit outillage du diamantaire. Le petit outillage du diamantaire. En dehors du matériel spécifique utilisé à chaque étape de la taille du diamant, un certain nombre de petits outils auxiliaires

Read More

Broyeur de branches mobile - DIAMANT 2000 - Albach

Découvrez toutes les informations sur le produit : broyeur de branches mobile DIAMANT 2000 de la société Albach Maschinen AG. Contactez un fournisseur ou directement la maison mère pour connaître le prix, obtenir un devis et

Read More

Broyeur de pierres - Tous les fabricants de

Trouvez facilement votre broyeur de pierres parmi les 47 références des plus grandes marques (MB, ...) sur AgriExpo, le spécialiste du machinisme et de l’équipement agricole pour vos achats professionnels.

Read More

Broyeurs de pierres - Vercom

Découvrez notre gamme de broyeurs de pierres VALENTINI conçus pour les tracteur de 70 à 450 cv et permettant de descendre jusqu'à 70 cm dans le sol. Service après-vente Contact

Read More

Broyeur de Pierres à Vendre: les Meilleures Solutions FAE

Broyage de pierres. Sur les chantiers routiers, d'infrastructures et de bâtiments, FAE propose une gamme complète de solutions dédiées au broyage de pierre en profondeur, au broyage de pierre en surface et au broyage de cailloux. Nos équipements offrent un niveau de productivité inégalable par rapport aux équipements de broyage classiques.

Read More

Bien choisir son broyeur de pierres en 6 points

2023.6.28 Cultures / Broyeur de pierres / Bien choisir son broyeur de pierres en 6 points. Pour faire face à des problèmes de pierres en densité importante, certains céréaliers investissent dans un broyeur de pierres.

Read More

Broyeur de pierres BP / BPR - D. GUTZWILLER

Agriculture. Fabriqués avec des aciers et des composants de haute qualité, les broyeurs BP et BPR excellent dans le broyage de pierres. Les broyeurs BP et BPR fonctionnent par percussion, au moyen de marteaux mobiles

Read More

Broyeurs de pierres pour tracteurs De 70 à 500

Broyeur de pierres pour tracteurs avec rotor à marteaux fixes. Puissance de 70 à 150 ch Diamètre max. de broyage Ø 15 cm max Profondeur max. de travail 15 cm max En savoir plus sur la broyeur de pierres STCL . STCM

Read More

Pack broyeur de végétaux thermique 212cc 60mm + 2 fers ST PIERRE

Jeu de 2 fers pour broyeur de végétaux thermique ST PIERRE DU CHAMP Réf 500338. Ce broyeur de végétaux thermique est équipé d’un puissant moteur de 212cc développant 4.1KW. Son diamètre de coupe de 60 mm et son rapport de réduction de 10:1 vous assureront un nettoyage efficace de vos coupes de végétaux lors de vos travaux d ...

Read More

Broyeur de branches Albach DIAMANT 2000 à vendre

A vendre Broyeur de branches Albach DIAMANT 2000 de 2021 disponible en France - Retrouvez toutes les caractéristiques de Albach DIAMANT 2000 sur Agriaffaires. Votre expérience sur notre site est une priorité. C’est pourquoi nous utilisons des cookies au titre de cet intérêt légitime à améliorer l’expérience utilisateur, réaliser ...

Read More

Broyeurs de pierres Pour Tracteurs, Pelles et Chargeuses

Une vaste gamme de broyeurs de pierres pour tracteurs, avec plus de vingt modèles, en mesure de broyer des pierres et des cailloux jusqu'à 50 cm de diamètre. Vous possédez un tracteur avec une puissance comprise entre 70 et 150 ch et vous devez broyer des pierres jusqu'à 15 cm de diamètre ? Les broyeurs de pierres FAE de la série STCL ...

Read More

Broyeurs de pierres et aligneuses Bugnot - Matériel agricole

3 天之前 Découvrez sur notre site la gamme de broyeurs de pierres et aligneuses proposée par Bugnot. Faites confiance à nos 100 ans d'expérience pour vous conseiller !

Read More

Broyeur de pierre - Sofranel Location

Détails. Broyeur de pierre sur tracteur 300 Cv L 2 000 mm. Broyeur de pierre sur tracteur 300 Cv... Broyeur sur tracteur, idéal pour différents types de travaux tel que : travaux routiers, préparation de sol agricole, création et réfection de chemins forestiers et coupe feu, ou encore traçage de pistes de ski.

Read More

Broyeur de géode - Stardew Valley Wiki

2024.5.12 Le Broyeur de géode est un équipement plaçable dans la ferme servant à ouvrir des géodes. Le joueur obtient son plan de fabrication après avoir complété la quête "Patrouille des cavernes", donnée par Clint. Le Broyeur ne peut pas ouvrir de trésor d'artefacts, ni de Noix de coco dorée. ... Lingot en or (2) Pierre (50) Diamant (1)

Read More

CHAÎNES AVEC PIERRES remplaçables 6 pièces tronçonneuse diamant broyeur ...

CHAÎNES AVEC PIERRES remplaçables 6 pièces tronçonneuse diamant broyeur à b - EUR 8,42. IN VENDITA! Chaînes avec pierres remplaçables 6 pièces tronçonneuse diamant broyeur à b 126490352325

Read More

diamant broyeur de pierres indonésie

2023.7.29 Trouvez un Broyeur de pierres parmi les 36 annonces de Broyeurs de pierres. 36 annonces disponibles Broyeurs ... 2000 - 1,0 m - Occasion - très bon état - Broyeur de pierres. polissage de pierres précieuses yogyakarta indonésie. ... négociant en diamant et pierres précieuses, Dépendant de la dureté des pierres à tailler, afin de ...

Read More

Pierres et Cailloux

L’andaineur de pierre est utilisé pour créer des andains en isolant les pierres de la terre, afin de faciliter le passage du broyeur de pierres et de gagner un temps important. Gamme Andaineur; OCCASIONS VENTES: Petites

Read More

Broyeur de branches automoteur - DIAMANT 2000 - AgriExpo

Découvrez toutes les informations sur le produit : broyeur de branches automoteur DIAMANT 2000 de la société Albach Maschinen AG. Contactez un fournisseur ou directement la maison mère pour connaître le prix, obtenir un devis et découvrir les points de vente près de chez vous.

Read More

Pack broyeur thermique 196cc 100mm + 2 fers ST PIERRE

Contenu du pack. Broyeur de végétaux et de branches thermique essence 196cc 100mm ST PIERRE DU CHAMP. Référence : 500331. Quantité : 1. Jeu de 2 fers pour broyeur de végétaux thermique ST PIERRE DU CHAMP Réf 500331. Référence : 109230. Quantité : 1. Paiement 100% sécurisé. Expédition 24/48h.

Read More

Diamant : L'évolution du cueilleur à maïs - Capello

Né avecle broyeur de tige. DIAMANT est né avec le broyeur de tige horizontal avancé. Pionnier dans l’utilisation du broyeur de tige horizontal grâce à ses 30 ans d’expérience, Capello a affiné ultérieurement cette technologie en garantissant une coupe encore plus au ras du sol et une qualité de coupe inégalée.

Read More

Broyeur de pierre - Achat / Vente pas cher avec prix sur

Broyeur de pierre. 81 produits trouvés. Le broyeur de pierre ou broyeur à cailloux est un équipement permettant de préparer le sol avant un semis ou un aménagement en broyant pierres et cailloux de gros diamètres. voir plus. Vendeurs. Type d'achat. Explorer les catégories. Broyeur de pierre Bugnot.

Read More

Broyeur de branches Albach d'occasion à vendre - France

Broyeur de branches Albach d'occasion à vendre ... Albach Diamant 2000, Rębak samojezdny, 2020rok, 700KM, Euro 6. 10 Vous avez masqué cette annonce. 2020 Broyeur de branches Pologne , Pomorskie Prix sur demande Filtres 1 ...

Read More

Broyeur FS22 - KingMods

2022.10.12 Téléchargez le mod Broyeur (Usines) pour FS22, Farming Simulator 22 sur KingMods. Téléchargez le mod Broyeur (Usines) pour FS22, Farming Simulator 22 sur KingMods. ... Produit de la pulpe de betterave sucrière à partir de betteraves sucrières, 600 cycles par mois et 168 pulpes de betterave sucrière sont produites par cycle.

Read More

Location broyeur de pierre location ramasseuse de pierre

Un tracteur de 80 CV suffira à animer la machine. Sa trémie élévatrice bascule à 2.30 M de hauteur pour un déchargement aisé (petite remorque, godet de télescopique ou bord de champs). BROYEUR DE PIERRE. Le broyeur de marque KIRPY, quant à lui, broiera les pierres en plein ou sur andain grâce à 34 marteaux carbures en son enclume fixe.

Read More

BPS - Broyeurs de pierres - KIRPY

5 天之前 Tous les broyeurs de pierres sont livrés avec transmission (Préciser la dimension et le nombre de cannelures côté tracteur). Attention : les Broyeurs BPS 200, BPS 250 et BPS 300 sont livrés avec des transmissions 6 ou 20 Can 1”3/4 (le constructeur se décharge de toute responsabilité pour l’utilisation d’une transmission en 1”3/8 ...

Read More

Pierre Diamant - Vertus des pierres - France

Symbolique de la pierre diamant. Surnommé “Reine des gemmes”, “reine des pierres”, le diamant est la larme de Dieu. Il symbolise la perfection, la pureté intacte. Il est associé à la foudre et au feu particulièrement, mais

Read More

Broyeur OBL'X Bugnot - Matériel agricole

2024.5.14 Les patins arrière contrôlent la profondeur de travail hydrauliquement. La cinématique de l’OBL’X permet de faire passer toute la puissance du tracteur au rotor, cela en fait un broyeur peu « tirant ». Le broyeur OBL'X proposé par Bugnot travaille à des profondeurs de 40cm. Faites confiance à nos 100 ans d'expérience pour vous ...

Read More

BPN - Broyeurs de pierre - KIRPY

5 天之前 BPN 200-250-300, Broyeur de pierre, Extirpation, andainage, ramasseuse de pierres, débroussailleur forestier, récolteuse asperge ou tabac : KIRPY est le spécialiste de l'épierrage, à travers sa gamme jaune et les outils GRENIER-FRANCO et BECKER.

Read More

Broyeur de pierres - Tous les fabricants industriels

Trouvez facilement votre broyeur de pierres parmi les 83 références des plus grandes marques (Liming, NEUE HERBOLD, LONGI, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos achats professionnels.

Read More

CHAÎNES AVEC PIERRES remplaçables 6 pièces tronçonneuse diamant broyeur ...

CHAÎNES AVEC PIERRES remplaçables 6 pièces tronçonneuse diamant broyeur à b - EUR 8,28. À VENDRE! Chaînes avec pierres remplaçables 6 pièces tronçonneuse diamant broyeur à b 126490352325. FR. Menu. PicClick USA

Read More

Diamant 2000 - Products - Albach Maschinenbau AG

DIAMANT 2000One of the most powerful all-road self-propelled chipper. The machine convinces by best chopping quality, off-road capability and durability. It is driven by a permanent all-wheel drive system with independent hydromechanical drive on the two main axles. This means that even hill climbs or rough terrain can be mastered with ease.

Read More

liste de prix de broyeur de pierre de diamant

Accuell > broyeur de pierre diamant prix > broyeur de pierre diamant prix 2020-09-23T04:09:44+00:00 Broyeur de pierres à prix mini ManoMano. Pertinence Prix Promotion 2 218 € 80 1 491 € 00 32 % DISQUE DIAMANT 350 MM BÉTON BATIMENT GRANIT PIERRE DURE MONTOLIT DNA LXS350 Livraison gratuite Ajouter au panier .

Read More

BROYEURS DE PIERRES STC - FAE

STC BROYEURS DE PIERRES MODÈLE STC/ST 125 STC/DT 150 STC/DT 175 STC/DT 200 Puissance tracteur (ch) 80-110 100-220 120-220 130-220 PDF (tours/min) 540-1000 1000 1000 1000 Largeur de travail (mm) 1340 1580 1820 2060 Largeur totale (mm) 1760 2010 2250 2490 Poids (kg) 1850 2450 2690 2830 Diamètre du rotor (mm) 550 550 550

Read More