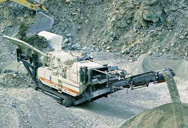

la destruction de broyage POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- tamiseur vibrant de karoube

- fabricant d équipement de carrière de bentonite

- usines de concassage mobile usa

- analyse des couts de lavage de sable

- matériel de production de ciment

- fabricants de broyeur de charbon

- entreprises minières dans la région de louest

- concasseur de roche promotion

- tonnes par balle heures moulin

- Concasseurs dans le commerce international

- trituradora y trituradora de piedra

- concasseur à mâchoires de lubrification automatique canada

- w50dc fraiseuse à froid

- molino de agua molinos venta

- matériau broyeur de pierres

de l usine de ciment en jordanie types

Broyeur de pierres - Tous les fabricants industriels

Trouvez facilement votre broyeur de pierres parmi les 83 références des plus grandes marques (Liming, NEUE HERBOLD, LONGI, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos achats professionnels.

Read More

STCM - Broyeur de pierres FAE

Broyeur de pierres pour tracteurs d'une puissance de 80 à 280 ch. Grâce au grand orifice d'entrée de matériau, il peut répondre aux besoins des professionnels qui doivent broyer des pierres jusqu'à 30 cm de diamètre et travailler jusqu'à une profondeur de 20 cm. La gamme STCM propose des modèles à transmission simple ou à double ...

Read More

Broyeur de pierres Boxing stone 2EF - broyeur de pierres

Le broyeur de pierres BOXING STONE 2F est spécialement conçu pour le broyage de pierres sur un sol souple ou préalablement travaillé. Les patins et le boîtier sont en acier HARDOX résistant à l’usure et sont interchangeables. Il est équipé de marteaux en alliage spécial à pointe en métal dur, ce qui les rend plus résistants et durables.

Read More

Broyeurs de pierres - Plaisance Equipements

Nos broyeurs de pierres permettent : Le broyage de pierres calcaires. Le broyage de la végétation. Un travail en conditions sèches et humides. Le broyage en plein des terrains agricoles pour éliminer les pierres. La remise en état des pistes et chemins forestiers. Le broyage des murets, haies et taillis autour des parcelles agricoles.

Read More

Broyeur de pierres - Tous les fabricants industriels - Page 2

Trouvez facilement votre broyeur de pierres parmi les 83 références des plus grandes marques sur DirectIndustry, le spécialiste de l’industrie pour vos achats professionnels. Page 2

Read More

dukungan broyeur de pierres de matériau

2024.3.3 Broyage des pierres Les solutions FAE Group sont la réponse adéquate lorsqu’il s’agit de broyer ou concasser les pierres et les cailloux (crushing et shredding) pour les travaux agricoles ou routiers: il est possible de réduire le volume des pierres et des riches en réutilisant le matériau sur place, pour la récupération des terrains agricoles,

Read More

Broyeur de minéraux - Tous les fabricants industriels

Trouvez facilement votre broyeur de minéraux parmi les 141 références des plus grandes marques (Liming, NEUE HERBOLD, SIEBTECHNIK, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos achats professionnels.

Read More

Broyage - Groupe Cheval

Broyage de pierre et de végétaux. Expert en broyage de pierres, de friches, de souches et de végétaux, Blanc BTP propose une solution économique afin de préparer tous vos terrains. Dans un souci de respect de l’environnement, les matériaux broyés peuvent être réutilisés en guise de remblai.

Read More

Nouveau broyeur de pierres STCM pour tracteurs jusqu'à

2024.2.21 FAE renouvelle le milieu de gamme de broyeurs de pierres en introduisant la nouvelle gamme STCM. Le nouveau broyeur, appelé à remplacer la gamme STC actuelle, peut broyer des pierres allant jusqu'à 30 cm de diamètre et jusqu'à une profondeur de 20 cm, pour une largeur de travail allant jusqu'à 230 cm. Le STCM est compatible avec les

Read More

Broyeur de pierres BP / BPR - D. GUTZWILLER

Broyeur de pierres BP / BPR. Fabriqués avec des aciers et des composants de haute qualité, les broyeurs BP et BPR excellent dans le broyage de pierres. Les broyeurs BP et BPR fonctionnent par percussion, au moyen

Read More

Broyeurs de pierres Pour Tracteurs, Pelles et Chargeuses

FAE propose un broyeur de pierres avec rotor à outils fixes pour chargeuse compacte, pour broyer des cailloux et des pierres jusqu'à une profondeur de 15 cm. ... Grâce à la présence des contre-couteaux réglables en acier antiusure, la STC/SSL broie le matériau à la granulométrie souhaitée, tandis que la porte hydraulique permet de ...

Read More

Nouveau broyeur de pierres STCM pour tracteurs jusqu'à

2024.2.21 FAE renouvelle le milieu de gamme de broyeurs de pierres en introduisant la nouvelle gamme STCM. Le nouveau broyeur, appelé à remplacer la gamme STC actuelle, peut broyer des pierres allant jusqu'à 30 cm de diamètre et jusqu'à une profondeur de 20 cm, pour une largeur de travail allant jusqu'à 230 cm. Le STCM est compatible avec les

Read More

STCM - Broyeur de pierres FAE

Broyeur de pierres pour tracteurs d'une puissance de 80 à 280 ch. Grâce au grand orifice d'entrée de matériau, il peut répondre aux besoins des professionnels qui doivent broyer des pierres jusqu'à 30 cm de diamètre et travailler jusqu'à une profondeur de 20 cm. La gamme STCM propose des modèles à transmission simple ou à double transmission.

Read More

Broyeur de pierres FAE STCM avec rotor à outils fixes pour

Broyeur de pierres FAE STCM avec rotor à outils fixes pour les tracteurs jusqu'à 280 ch. Grâce au grand orifice d'entrée de matériau, il peut répondre aux besoins des professionnels qui doivent broyer des pierres jusqu'à 30 cm de diamètre et

Read More

Plaques de mâchoires de broyeur de manganèse

Machines Qiming plaques de mâchoire le matériau comprend des plaques de mâchoire en manganèse, des plaques de mâchoire à inserts TIC et des plaques de mâchoire en acier allié. Table des matières cacher. 1 Plaques de mâchoires de broyeur de manganèse. 1.1 Composition chimique élevée en manganèse mécanique. 1.2 Différentes pierres ...

Read More

Broyeur de pierres - Tous les fabricants industriels

Trouvez facilement votre broyeur de pierres parmi les 83 références des plus grandes marques (Liming, NEUE HERBOLD, LONGI, ...) sur DirectIndustry, le spécialiste de l’industrie pour vos achats professionnels. ... vitesse de broyage du matériau introduit est de quelques secondes quel que soit le type de matériau. La machine, en montant l ...

Read More

matériau broyeur de pierres

Concasseur de pierres usine coût ethiopie fabrication de. dolomite stone crusher malaisie gold ore crusher Prix de broyeur à percussion Mobile Iron Ore en exportateur iro minerai . Read More fr/fournisseur de concasseur de mâchoires de dolomite en indonésie. Contribute to liyingliang2022/fr development by creating an account on . Read More

Read More

Broyeur de pierres Boxing stone 2EF - broyeur de pierres

Le broyeur de pierres BOXING STONE 2F est spécialement conçu pour le broyage de pierres sur un sol souple ou préalablement travaillé. Les patins et le boîtier sont en acier HARDOX résistant à l’usure et sont interchangeables. ... Double châssis interchangeable en matériau anti-usure. Roulement du rotor. Roulement du rotor à double ...

Read More

BROYEURS DE PIERRES STC - FAE

Broyeur de pierres pour tracteurs avec rotor à marteaux fixes. ... Lame à niveler. Lame doseuse. pour niveler le matériau broyé ... STC/3 (standard) Broyeur de pierres conçu et fabriqué pour répondre . aux exigences des professionnels qui ont besoin de . broyer des pierres jusqu’à 30 cm de diamètre et de . travailler jusqu’à 20 cm ...

Read More

Broyeur de pierre et de cailloux pour fabrication de béton

2024.4.30 Concasseurs de pierres et de galets dans la production de béton : une pierre angulaire de la qualité Dans la construction, le béton règne en maître comme matériau de construction omniprésent. Sa polyvalence, sa durabilité et sa résistance le rendent indispensable pour un large éventail de structures, des gratte-ciel imposants aux ...

Read More

Nouveau broyeur de pierres STCM pour tracteurs jusqu'à

2024.2.21 FAE renouvelle le milieu de gamme de broyeurs de pierres en introduisant la nouvelle gamme STCM. Le nouveau broyeur, appelé à remplacer la gamme STC actuelle, peut broyer des pierres allant jusqu'à 30 cm de diamètre et jusqu'à une profondeur de 20 cm, pour une largeur de travail allant jusqu'à 230 cm. Le STCM est compatible avec les

Read More

BPS - Broyeurs de pierres - KIRPY

5 天之前 Tous les broyeurs de pierres sont livrés avec transmission (Préciser la dimension et le nombre de cannelures côté tracteur). Attention : les Broyeurs BPS 200, BPS 250 et BPS 300 sont livrés avec des transmissions 6 ou 20 Can 1”3/4 (le constructeur se décharge de toute responsabilité pour l’utilisation d’une transmission en 1”3/8 ...

Read More

Broyeur de pierres - Tous les fabricants de l'agriculture

Trouvez facilement votre broyeur de pierres parmi les 47 références des plus grandes marques (MB, ...) sur AgriExpo, le spécialiste du machinisme et de l’équipement agricole pour vos achats professionnels.

Read More

STCM - Broyeur de pierres FAE

Broyeur de pierres pour tracteurs d'une puissance de 80 à 280 ch. Grâce au grand orifice d'entrée de matériau, il peut répondre aux besoins des professionnels qui doivent broyer des pierres jusqu'à 30 cm de diamètre et travailler jusqu'à une profondeur de 20 cm. La gamme STCM propose des modèles à transmission simple ou à double transmission.

Read More

Fabricant de concasseurs et broyeurs – Concasseurs de pierres

2024.5.9 Équipement de broyage; Matériau; Contactez-nous; ... Concasseurs de pierres, broyeurs industriels et leurs pièces détachées. for: Menu. Accueil; À propos de nous; Équipement de concassage. Concasseur à mâchoire série C6X; ... Broyeur à pendule série MB5X; Matériau.

Read More

Pierre (matériau) : définition et explications - Techno

2024.5.14 le coût d'extraction du matériau en carrière ; le coût d'acheminement du matériau (brut ou taillé) jusqu'au lieu de construction ; le coût de préparation du matériau (par exemple, taille des pierres en blocs parallélipédiques) ; le coût de l'appareillage. Pour le bâtisseur, la pierre est un matériau de construction. Les pierres ...

Read More

Broyeur de pierres Boxing stone - broyeur de pierres - Lagarde

Le broyeur de pierres BOXING STONE est spécialement conçu pour le broyage de pierres sur un sol souple ou préalablement travaillé. Les patins et le boîtier sont en acier HARDOX résistant à l’usure et sont interchangeables. Il est équipé de marteaux en alliage spécial à pointe en métal dur, ce qui les rend plus résistants et durables.

Read More

Broyeurs de pierres pour tracteurs De 70 à 500 CH - FAE

Broyeur de pierres pour tracteurs avec rotor à marteaux fixes. Puissance de 80 à 190 ch Diamètre max. de broyage Ø 30 cm max Profondeur max. de travail 28 cm max En savoir plus sur la broyeur de pierres RSL . RSM . Le broyeur de pierres pour les travaux exigeants.

Read More

Mur en pierre : prix, pose, avantages,

Construire un mur en pierre est loin d’être une tâche facile, découvrons ensemble les caractéristiques de ce matériau ainsi que la bonne méthode et les différentes étapes à suivre pour une construction correcte d’un mur

Read More

Broyeurs de pierres Pour Tracteurs, Pelles et Chargeuses

FAE propose un broyeur de pierres avec rotor à outils fixes pour chargeuse compacte, pour broyer des cailloux et des pierres jusqu'à une profondeur de 15 cm. ... Grâce à la présence des contre-couteaux réglables en acier antiusure, la STC/SSL broie le matériau à la granulométrie souhaitée, tandis que la porte hydraulique permet de ...

Read More

Broyeur pierre et cailloux pour les carrières de granulats

2024.4.26 3. Concasseurs à percussion : Qu'il s'agisse d'impacteurs à arbre horizontal (HSI) ou d'impacteurs à arbre vertical (VSI), ces concasseurs excellent dans la production de granulats fins avec une forme de particules supérieure. Les concasseurs à percussion sont particulièrement efficaces pour traiter des matériaux friables et atteindre ...

Read More

[Test, avis, prix] Broyeur de végétaux Bosch AXT 22 D

2024.5.3 Notre avis. 0%. Conçu pour simplifier l’installation et l’utilisation, le broyeur électrique Bosch AXT 22 D est doté d’un entonnoir autonome qui guide les végétaux vers le rotor de coupe pour un traitement efficace. Il est ainsi possible de traiter de grands volumes de déchets végétaux en toute sécurité.

Read More

Broyeur de Pierres pour Chargeur Compacte De 90 a 120

Broyeur de pierres pour mini chargeur compacte avec rotor à outils fixes. Broyer cailloux et pierres jusqu'à une profondeur de 15 cm. ... Grâce à la présence des contre-couteaux réglables en acier antiusure, la STC/SSL broie le matériau à la granulométrie souhaitée, tandis que la porte hydraulique permet de régler le dosage. ...

Read More

5 Types de broyeur de pierres de tracteur à vendre

Aucun résultat . Maison; Des produits; Cas; Blog; À propos de nous; Contactez-nous; Facebook Twitter Instagram LinkedIn Whatsapp

Read More

La pierre de construction, matériau du développement

2024.4.26 12. la pierre de construction, matériau du développement durable. Un matériau fragilisé par les pollutions modernes, à adapter aux usages. Comme tout matériau, la pierre de construction subit au fil du temps des processus d’altération, domma- geables pour l’esthétique et la conservation des bâtiments.

Read More

Accueil - Pierre Naturelle Distribution à Maupertus grand choix de ...

Entreprise de distribution et spécialiste en dallage schiste granit maçonnerie en pierre naturelle dans le nord cotentin à maupertus couverture en ardoise escalier paysage jardin mineral pavé en grès gonneville près de cherbourg. ok. Accueil; Services PND; Notre catalogue . Notre catalogue; Revêtement de sol;

Read More

Broyeurs de Pierres - Haute de Gamme FAE

FAE propose un broyeur de pierres avec rotor à outils fixes pour chargeuse compacte, pour broyer des cailloux et des pierres jusqu'à une profondeur de 15 cm. ... Grâce à la présence des contre-couteaux réglables en acier antiusure, la STC/SSL broie le matériau à la granulométrie souhaitée, tandis que la porte hydraulique permet de ...

Read More

Broyeur de pierres FAE STCM avec rotor à outils fixes pour

Broyeur de pierres FAE STCM avec rotor à outils fixes pour les tracteurs jusqu'à 280 ch. Grâce au grand orifice d'entrée de matériau, il peut répondre aux besoins des professionnels qui doivent broyer des pierres jusqu'à 30 cm de diamètre et

Read More